Print Finds New Horizons In The Internet Age

Technology, for all of its challenges, changes civilizations, cultures and histories. Even the Pony Express was a sort of new technology in its day – messages could traverse America from the Atlantic to Pacific faster than ever before – 10 days! If we think the pace of technology change is fast today, consider that the Pony Express lasted only 19 months before the telegraph replaced it and reduced message delivery times to seconds.

Most historians agree that the invention of the modern printing press by Gutenberg around 1440 is the most significant technology invention since the wheel. Despite ‘moveable type’ being pioneered 600 years earlier in China, it was the first time non-oral mass information could be disseminated and enabled the reformation and then the renaissance.

Today, printing shares its function as an information medium with email, facebook, Twitter and countless other internet applications but is still irreplaceable for many needs such as manuals, hand-out brochures, catalogues, business cards and of course packaging, decoration and signage.

Print world gathers in Germany

This was more than demonstrated at the recent international printing trade fair called drupa (from the German ‘druck’ meaning print and ‘papier) held in Düsseldorf during June. This event, held every four years, is the focal point for new and emerging print technologies, with over 260,000 attending in 2016, from 183 countries.

Australia and New Zealand were well represented, with an estimated 2,600 visitors from this region, including Oceania. Several pieces of equipment on the huge show floor – seventeen halls spread over 158,237 square metres of nett space – sported ‘sold to Australia’ signs including an eight-colour Ryobi press with environmentally-friendly LED UV coating to CMYK hub, a huge eight-colour plus double coater manroland Evolution 700 destined for Labelmakers of Victoria, several of HP’s new Indigo 12000 B2 digital presses and four of the exciting Landa Nanographic digital printing presses.

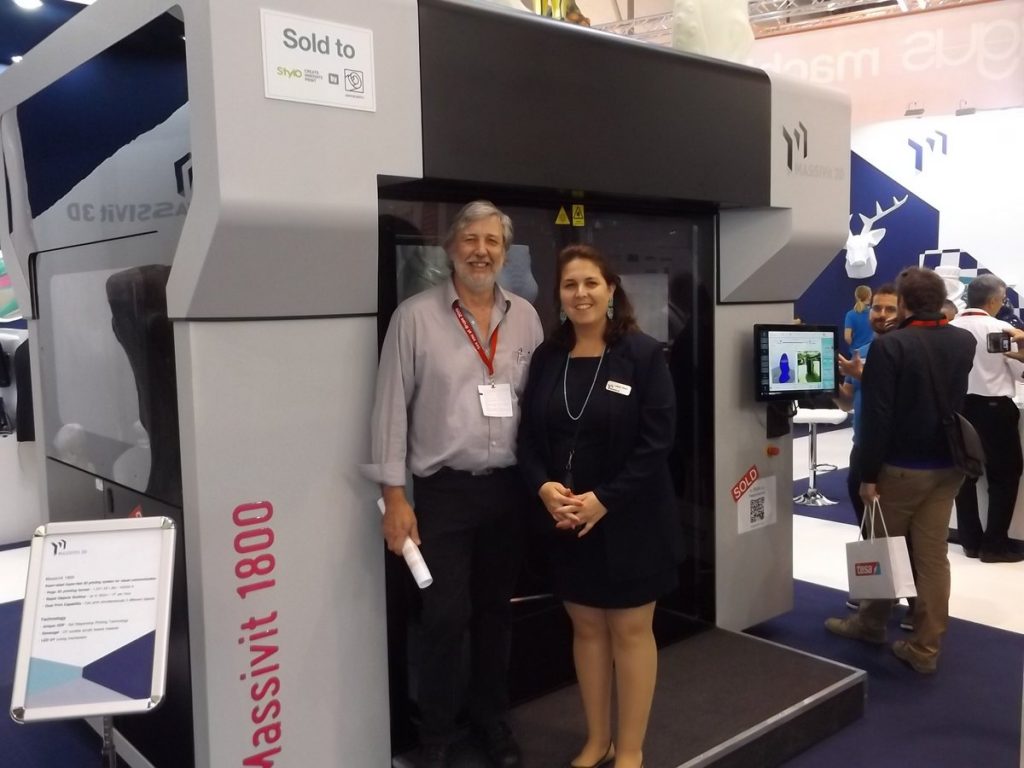

The emerging world of 3D printing was not overlooked with the largest commercially-available 3D machine, the Massivit 1800 from Israel, reporting 2 sales to Melbourne and Sydney respectively. These will mostly be used for point-of-sale display production, short-run models and signage.

Modern printing is not just about putting colour down on sheets at high speeds; digital printing has enabled specialized niches to emerge where just a few – even only one – product can be cost-effectively produced for testing, small batch or custom purposes. Digital technology has now impacted on the print finishing and embellishing sector, with equipment from Scodix, MGI, Landa, Kurz, Duplo, Highcon and others now able to transform flat sheets into superb showpieces of value-added print with spot varnishes, metallic foiling, die cutting, embossing and raised images. This is proving particularly popular in the packaging sector where formerly plain cartons and boxes can look like colourful major brands with embellishment, while keeping costs down to short runs on an ’as needed’ basis.

Adding sizzle to the printed sausage

Let’s start with a new product from Landa Nanotech, named after the ‘father’ of modern digital printing Benny Landa, who now runs the Landa Corporation. Apart from the upcoming new Nano-presses; there is Landa Metallography – a technology that can be fitted inline on existing label and packaging presses for metallic foil effects with zero-waste and reduced costs.

Currently, all hot stamp and cold foiling embellishment produces huge waste as it is applied using dies from rolls of foil. Whatever is not used to impress the gold, silver or other metallic effect onto the paper or board, becomes waste. So, if a wedding invitation in silver says ‘Invitation to Jack and Jill’s wedding’ only those letters are foiled and the rest of that area of the roll becomes unusable.

Landa’s Metallography uses metallised ‘NanoFlakes’ of particles so there is virtually no waste at all. Furthermore, no dies are needed as it is a digital process. The Metallography unit is retro-fitable on existing label and carton presses. The savings are remarkable, with Landa claiming 1kg of NanoFlakes replaces 3,000kg of foil.

Print embellishments are more than just foil. Two companies have digitalized the spot UV-varnishing process and gone even further with textures and raised areas. Scodix, another Israeli company, has enjoyed good success with its digital UV Enhancement presses that deliver high-gloss spot coating onto both offset and digitally-printed stock. The traditional method is screen UV where a stencil needs to be made, clear coat squeegeed on and an intense UV curing tunnel deployed. With Scodix, the spot UV can vary print-to-print and job change-overs are fast and clean. Several Scodix machines are in operation in Australia, including at Print2day’s main offset supplier. A metal foil station was introduced at the drupa exhibition.

MGI is a clever French company also offering stunning spot UV coating effects with its JetVarnish. MGI is 40% owned by Japanese giant Konica Minolta, who have incorporated the JetVarnish into its KM-C B1-size folding carton digital press previewed at drupa. Inline foiling is also possible which means a short-run, variable data box and carton press can take plain board in one end and deliver elaborately printed and embellished cartons out of the other, ready for die-cutting. Maximum sheet size is 760mm x 1060mm; max thickness 1.2mm and speeds of up to 2,200 sheets per hour are achievable.

British manufacturer Autobond is another company now offering inkjet spot UV machines aimed at short-runs – with the added benefit of inline lamination if required.

The world’s leading metal foil producer – Leonard Kurz – has also entered the digital arena with its ‘Digital-Metal’ which takes an entirely different approach. Used with toner digital machines, the area to be foiled in printed, then a foil with carrier film laid over the top. When peeled off, the metal foil adheres to the toner and the sheet is then ready for additional offset or digital printing.

In the label market, HP Indigo has long held pole position in digital production but drupa 2016 saw new entrants with narrow-web presses using inkjet and even toner. Where the HP Indigo technology is extending is at the finishing end, thanks to its partnership with ABG, a UK company making inline finishing for label web presses. ABG’s Digicon 3 series now offers inline die-cutting and kiss-cutting of labels, hot foil application, embossing, a flatbed screen process station and of course reel slitting, stripping and rewinding.

Digital embellishing of print delivers a very professional look and is no longer the sole realm of major companies ordering long runs. Business cars, brochures, catalogues, point-of-sale, presentation manuals and so on can all receive that ‘extra touch’ that adds prestige to a brand, product or service.

Print changing, but still growing

As print explores new horizons in an increasingly internet-centric world, some areas such as pure informational print, phone directories eg, will decline but new areas are rising up for SME businesses to project their image professionally. Catalogues continue to be the preferred browsing and decision-making medium for consumer durable and FMCG categories. An Australian Catalogue Association survey puts catalogues #1 in influencing consumer spending, with 77% of Australians spending on average 29 minutes per week browsing catalogues and brochures.

The drupa 2106 event showed just how much the print industry has transformed – the largest exhibitor was HP and the next few largest included names such as Canon, Konica Minolta, Fuji Xerox, Ricoh, Kodak and Epson – all digital short-run technologies. Even offset industry leader Heidelberg added an all-new B1 inkjet digital press to its range, co-developed with Fujifilm using its Dimatix Samba printheads and inks.

Yes, print is changing but it will always be with us. Worldwide, the printing market will reach USD$980 billion (AUD$1.28 trillion) by 2018 according to a well-respected Anglo-American research organization.

The next giant drupa expo is in 2020 – who knows what new technologies we will have by then to add value to printing: and success for print customers?

The next giant drupa expo is in 2020 – who knows what new technologies we will have by then to add value to printing: and success for print customers?